Beverage industry

ACLA grips the bottles the right way

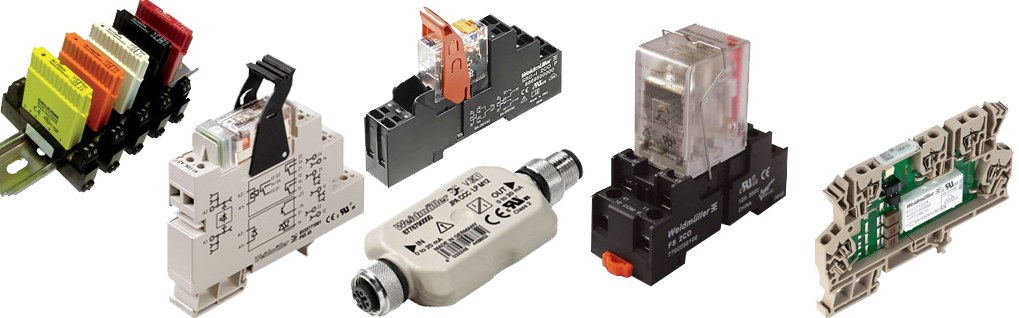

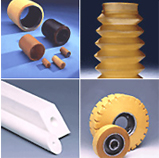

Construction elements of ACLATHAN for the beverage industry.

Enormous running speeds and shorter cycles of efficient packers

and unpackers in the beverage industry require reliably functioning

moulded parts and materials guaranteeing a long service life at the same

time.

The possibilities in mixing compounds of the PUR-elastomer

ACLATHAN meet this demanding requirement profile fully. Moulded parts of

ACLATHAN P and ACLATHAN KH for the beverage industry offer excellent

properties to the technical user and consequently a high economical

efficiency during the operation.

The ACLA product program for the beverage industry:

- Grippers and "long life grippers"

- Pressure rings

- Filler cones

- Bottle pads

- Combination rollers

- Suction cups

- Seals

The material advantages:

- High wear and tear propagation resistance

- Food compatibility

- Very good mechanical resistance

- High adhesion and grip

- Wide temperature range

- Good hydrolysis resistance

Handling

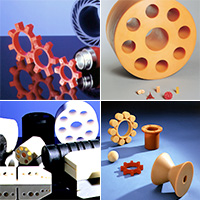

Gentle and reliable handling of goods using suction cups and grippers from ACLATHAN®-P und ACLATHAN®-AP

Gripping elements used in pneumatic handling are subject to extreme strains.

The suction cups and grippers made by ACLA-WERKE using the high-grade water-crosslinked PUR-elastomers ACLATHAN P and ACLATHAN AP are adapted to these special requirements and convince by many advantages:

- High mechanical strength

- Extremely long service life

- Extraordinary abrasion resistance

- High tensile and tear propagation strength

- Insensitive to burrs and sharp edges

- Good adhesion and grip

- Ideal adjustment between elasticity and strength

- Ttemperature range from - 40° C (- 40° F) to + 80° C (+ 176° F)

- Excellent resistance against hydrolysis (ACLATHAN AP)

Especially the extremely long service life, also under roughest

operation conditions, contributes essentially to an increased economy in

the whole material handling field by a reduction of down-time. This is

the case with the handling of parts in the paper, cardboard and

packaging industry, in the glass and metal industry, in wooden sheet

processing, car production, plastic and ceramic industry.

ACLA-WERKE offer a comprehensive article program for the product

field suction cups and grippers which are available with or without

adapterrs and reducers.

Printing industry

ACLA PUR elastomers for printing

Modern printing and finishing machines require components with

high precision, reliability and economy. ACLA-moulded parts for the

printing industry made of the homogeneous PUR-elastomer ACLATHAN and the

cellular PUR-elastomer ACLACELL stand up to these requirements in an

ideal way.

Special compounds adapted to the special requirements of the

printing industry guarantee a safe functioning and extremely long

service life of all parts.

The ACLA article program for printing and finishing machines:

- Cutting bars

- Knife cushions/combined knife cushions

- Damping bars

- Suction cups

- Feed rollers

- Cylinder coatings

Squeeges from ACLATHAN: for screen printing

ACLA-WERKE offer a comprehensive range of high-grade squeeges for all cases of the daily screen printing practice which set a standard in the screen printing world thanks to a long experience in the application. The screen printer has a choice between different profiles and Shore-hardnesses ranging from 65 Shore A to 90 Shore A as well as combination blades covering different jobs.

Transport and materials handling

ACLA keeps the industry rolling

Rollers, wheels and tires with the ACLA logo are used in different fields of industry. Constant development work, tailor-made materials and the consequent analysis of experience in applications have led to an efficient product program which can offer a suitable solution for any requirement.

Fields of application:

Fields of application:

- Forklift trucks

- Electric monorail systems

- General engineering

- Industrial assembly lines

- Packaging machines

- Textile machines

- Municipal applications, for example sewage-treatment plants and others

General engineering

Against noise and wear

Polyurethane elastomers from ACLA for engineering.

Where noise, wear and dynamic requirements are existing there are ideal possibilities

to use moulded parts of high-grade cellular and homogeneous PUR-elastomers from ACLA.

The excellent properties of these efficient materials concerning

wear and tear resistance, compression set, noise damping and medium

resistance enable many applications in the whole engineering field.

- Seals for hydraulic and pneumatic cylinders,

for examples U-cups, scraper rings, rod seals, radial seals etc.

- Damping elements and springs

- Coatings as wear and noise protection

- Drive and coupling elements

Lift Industry

Your partner for innovative and proven components used by the lift industry

As manufacturers and developers ACLA-WERKE are partners of the lift industry with their products for more than 4 decades. The intensive cooperation with many well-known lift manufacturers all around the world has led to special mounting elements which are exactly adapted to the requirements of the lift industry. Besides the quality requirement and the reliability of the components the ACLA product program for the lift industry is distinguished by functional and maintenance-free constructions.

The delivery program for the lift industry:

- Buffers with EC type test certificate, CE tested

- Guide shoes

- Guide shoe inserts

- Many guide elements

- Rail lubricator (oiler)

- Oil collector

- Roller guides

- Rope suspension springs

- Pulleys